Iraq, a country that has weathered countless storms and vicissitudes, is now rejuvenating at an astonishing pace. The political situation is becoming increasingly stable, and economic reforms are deepening. Today, Iraq is like a rising star, becoming an investment hotspot sought after by global capital with a brand new attitude. What is particularly noteworthy is that the Iraqi government continues to increase its investment in infrastructure construction, and the huge business opportunities contained in post-war reconstruction are like a tempting "cake".

Under the grand framework of the "the Belt and Road" initiative, China and Iraq have established a strategic partnership, which has continuously injected strong impetus into bilateral economic and trade exchanges. The pragmatic cooperation between China and Iraq continues to deepen. In this hopeful land of Iraq, numerous Chinese funded enterprises actively integrate into the local economic and social development, create a series of livelihood projects, actively participate in local social construction, and carefully cultivate localized professional talents, bringing substantial benefits to both countries and their peoples. Many Chinese funded enterprises have been involved in the reconstruction of Iraq, and H Construction Group is one of them.

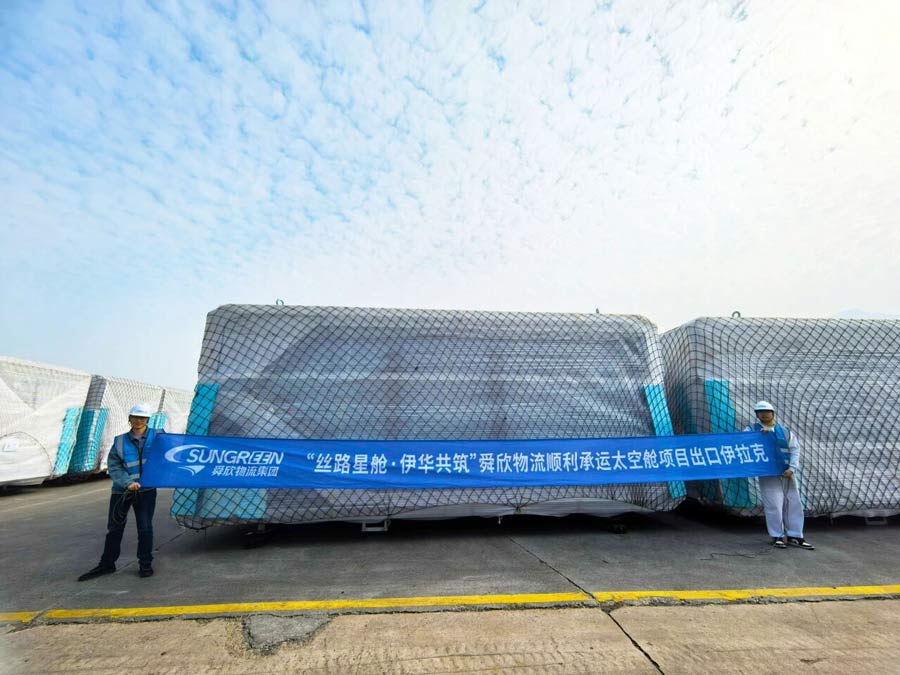

H Construction Group urgently needs to export a batch of spacecraft modules for accommodation from China for its infrastructure project in an oil field in Iraq. However, how to efficiently transport this batch of goods to the destination has become a serious challenge in front of us.

Space capsule, a technological product of modular design, has become an indispensable carrier for infrastructure construction in remote and harsh areas with its unique advantages. It has the advantages of lightweight, strong weather resistance, and complete internal facilities, especially suitable for infrastructure camps in remote and harsh areas. But behind the advantages of the spacecraft lies its complex logistics properties. It has a large volume, with a single weight of 4-7 tons and a size far exceeding the capacity of a 20HQ container, making it a non-standard cargo with ultra wide and ultra high dimensions.

If a conventional 40 foot frame container is used for shipping, it not only incurs high costs, but is also limited by container ship space and stacking restrictions, making it difficult to ship large quantities of goods in one go. Faced with many challenges such as tight delivery time, high value of goods, and harsh transportation conditions, H Construction Group urgently needs a reliable logistics partner who can connect the entire domestic and international chain and provide customized solutions. However, there are only a few logistics companies on the market that can fully handle the entire shipping chain of this spacecraft.

After receiving the client's commission, Sungreen Logistics quickly integrated domestic and foreign teams, and carefully developed a complete set of scattered cargo ship transportation plans based on the characteristics of the spacecraft and customer needs, as well as the unique features of the spacecraft and specific customer requirements. This plan covers a detailed full chain shipping plan from document preparation, factory pick-up and warehousing, to booking, customs clearance, destination port clearance, and project delivery. The strategy of choosing bulk carriers for transportation is a decision made by Sungreen Logistics based on years of rich experience in the international logistics industry and comprehensive consideration of project risks.

As is well known, the transportation of miscellaneous goods by bulk carriers is not easy, and booking bulk carriers is undoubtedly a deep test for logistics companies. Most ships only dock at small ports along inland rivers such as Taicang, Changshu, and Zhangjiagang, and there are few options for docking at large or hub ports. In addition, many factors such as weak coordination ability of ship owners, high transportation costs, and restrictions on cargo volume thresholds have become numerous difficulties in the booking and shipping process. However, Sungreen Logistics has efficiently integrated end-to-end resources with its strong resource integration capabilities, forming a complete resource loop.

In response to the non-standard characteristics of the ultra wide and ultra high space capsule, Sungreen Logistics did not choose the expensive 40 foot frame container ship transportation method, but instead adopted bulk cargo ship transportation. Lianyungang, as a convenient port for bulk cargo ships to dock, provides unique conditions for this transportation. And with the core advantage of being a first-class booking agent for numerous bulk cargo ships, Sungreen Logistics quickly coordinated and locked in the same shipping company and voyage space at contract prices. This measure not only avoids intermediary premiums and significantly reduces customer logistics costs, but also ensures that all goods can be shipped on the same ship at once, effectively avoiding the risk of delays that may arise from partial transportation.

The prologue of transportation begins with arranging professional trailers to pick up goods from the factory. As the staff skillfully lifts more than 30 spacecraft onto the low board truck, this massive low board fleet slowly drives out of the factory, rolling wheels and raising dust all the way, heading towards the Lianyungang yard. The orderly descent of the spacecraft also laid a solid foundation for subsequent sea voyages.

The Sungreen Logistics team has demonstrated a high level of professionalism and meticulous work attitude in the crucial process of cargo loading and reinforcement. During the storage period of the goods at the Lianyungang yard, the team, together with the shipowner, personally went to the yard for on-site inspection. Both parties jointly discussed and formulated a professional and rigorous reinforcement plan. From the selection of the landing location to the implementation of protective measures, every detail has been carefully considered and repeatedly scrutinized to ensure that the spacecraft can maintain stability during the long journey and avoid unexpected situations such as overloading.

On November 19, 2025, with precise instructions being conveyed one after another, the crane at Lianyungang Port operated in an orderly manner, and all spacecraft were officially loaded onto the ship under the operation of professional personnel. On the 23rd, the ship carrying this batch of modular prefabricated houses carrying the hope of reconstruction officially set sail. After a long journey of over 30 days, the goods safely arrived at the destination port on December 22nd. During this period, the Sungreen Logistics team remained steadfast in their position, closely monitoring the progress of each link to ensure a tight and seamless connection between them. After arriving at the destination port, the local team immediately intervened, quickly completed the customs clearance procedures, and arranged for professional trucks to deliver the goods in bulk directly to the project site. We have achieved efficient and collaborative end-to-end closed-loop services both domestically and internationally, earning high praise and full recognition from our customers.

The successful completion of this transportation task is not only a simple logistics task, but also an interpretation of Sungreen Logistics' professional strength in the fields of bulk and large cargo logistics. As a long-term service provider specializing in international logistics of dangerous goods, Sungreen Logistics has also accumulated rich experience in general cargo and non-standard transportation, demonstrating strong resource integration capabilities, accurate scheme design capabilities, and full process control capabilities.

However, little known is that Sungreen Logistics' success in every shipment task is not solely based on accumulated experience. In the early stages of the plan development, Sungreen Logistics tailored multiple emergency plans for the shipment of this ticket to systematically dismantle potential hazards and ensure quick response in the face of unexpected situations.

Under the guidance and promotion of the "the Belt and Road" initiative, Sungreen Logistics is willing to help more Chinese intelligent manufacturing and Chinese infrastructure go global with professional and reliable logistics services, and contribute to the professional strength and responsibility of Chinese logistics enterprises for global sustainable development. In the future, we will continue to work together with partners to shoulder the responsibility of international logistics, and contribute the wisdom and strength of Chinese logistics to global reconstruction and development with safe, efficient, and customized logistics solutions.